Autopilot Troubleshooting & Testing

A $15,000 box, or a $2 crimp…

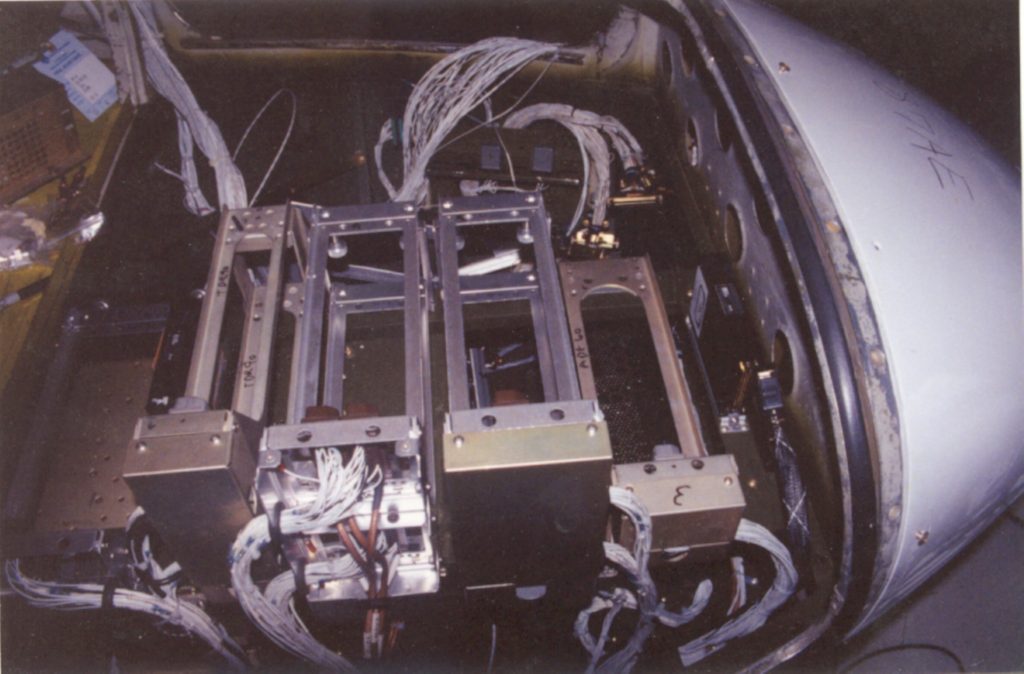

The most unnoticed component of the system is the wiring harness assemblies, upwards to a 1/4 mile of wire, and all of the rest of the parts that interconnect it, feeding power, ground, and the myriad of other vital data. Some of the data comes in the form of millivolts of analog voltage providing track error, and valid information.

An expanded understanding of how and why the system works will put you further toward the resolve, and is very much where I begin the process.

The first step is to isolate problems in the system. This is done by relating how to perform very specific checks, and watching for very specific results, while performing ground tests as well as flight observations. Once the problem is identified, if needed, I can guide your local maintenance facility thru resolving it by sharing hands on experiences spanning decades. This includes isolating problems with individual autopilot components, system wiring harnesses, connectors, peripheral switches, relays, as well as, airframe issues, and sometimes even plain old pilot error. In the event we find the need to send out for any repairs, I can recommend a few notable shops that are willing to look for a specific problem and repair as needed, rather than the “overhaul” mentality we see so often.

To be clear, any and all determinations of airworthiness after my involvement, is the sole responsibility of the pilot in command.

For this reason I must include the following statement.

I make no warranty or guarantee as to the airworthiness of any component, part or Autopilot that is the subject of his consultation. Webair does not warranty or guarantee any repairs or alterations made as a result of his consultation. It is the responsibility of the Pilot in Command to determine the airworthiness of his or her aircraft and its components.